At Least They Are Round

In Japan hobby printing is fraught with pitfalls -- some in the rollers

by Sheldon C. Wesson

- Originally published in Al Fick's Heritage #1 for April 1956, this article won the AAPA's 1955-56 Essay Laureate award and was reprinted in the September 1956 (Vol. 20, No. 6) American Amateur Journalist.

When in the course of printing the press-rollers become so hard that even the rats won't chew them, slur is the result. So it was for two maddening days with SS [Siamese Standpipe] 33, and sad was the product thereof. The printer steeled himself to the necessity of having new rollers cast. The Japanese "all-weather" had proven to be just that--equally lousy in all weather.

Heretofore I have given the old rollers to the firm which does commercial printing for my business needs here. This time I took the rollers down to the manufacturer myself (with the indispensable interpreter in tow) to ask if he couldn't do something to improve the mixture--another ounce of camel sweat or hydrogen periphery or something.

The roller company is innocently named Seikosha which means simply Seiko Company. The "factory" could easily pass for the Yokohama Stink-Bomb and Sewer-Sludge Works.

The factory is located conveniently behind the home of the President and Chief Mixer. It occupies a shed of approximately 60 square feet; and continues to occupy its location only because the President's house protects it from strong winds and keeps small boys from banging it down with their agressive tricycles.

The Compound Preparation Department consists of two parts: Below is the Calorific Maintenance Sub-Unit, a bunch of rocks held together by 11 yen worth of cement and containing a wood-fire; above is the Compound Reduction Department, a pair of five gallon tins which recently contained GI salad oil. Maybe still do.

Raw materials are obtained by carefully stripping the old composition from rollers brought in for recasting--mildew, old ink, sludge, trash and corruption. (An extra dash of corruption for winter-grade rollers.)

Seikosha recently patented a sludge-removal unit which serves to dispose of the accumulated whatsit that floats on top of the melted mess. It is cunningly fashioned of a bamboo pole to the end of which is tied an old saucepan, no longer needed in the kitchen of the adjoining residence. When not in use, this pot may be conveniently rested on the dirt floor. Pot Patent Pending.

After resting conveniently on the dirt floor, the same Potented Pat may also be used conveniently (Obviously an age of convenience.--Ed) to pour the melted gunk into the molds which form the rollers.

Casting molds for the rollers consist mainly of odd lengths of brass pipe, of sizes carefully graduated to be either a trifle too small or a trifle too large for the roller size as indicated by the roller-trucks.

The shop is, of course, electrified. A wire emerges from the window of the adjacent house, enters the door of the factory and terminates in a 25-watt bulb, hung at a height which also provides amusement and recreation when tall foreigners visit.

The shop is also air-conditioned. The door may be closed sometimes.

Rollers leaving this factory are first seasoned. They are carefuly leaned against the...errr...building, so that they receive the full benefit of the dust kicked up by scurrying children, passing bicycles and vagrant breezes. Also whatever wash-water happens to be tossed out of nearby windows. The result is that rollers are thoroughly seasoned. After this they can stand anything.

My interpreter, Takazawa-san, has long since learned to translate everything I say with a straight face. He never knows when I am kidding. So, through him, I asked the Chief Chemist what was the difference between summer and winter rollers. He confided only that he "made a different medicine" for winter; and I was satisfied that at least there is a difference between his seasonal mixtures. After all, printing rollers the world over are sensitive to variations in temperature and moisture--and here humidity variations are extreme.

Six years in Japan have taught me not to be surprised when a sow's ear of a shop turns out a gem of a product. And the rollers work fine, for a few months. So I am resigned to semi-annual recastings, with no pain: The set of three rollers for the old 7x11 cost just $1.25.

PS. Four Standpipes and nine months have intervened since the above was written. The rainy season was short and dry, but the summer was long and damp. The rollers absorbed so much moisture that they wouldn't even pick ink off the plate! Even with a coating of oil, the rollers swelled, rotted and acquired a coat of mildew. Looked like the world's only set of rollers wrapped in greenish-white flannel.

PPS: The rollers on the press now come from a new maker. They had to be re-cast before using, too!

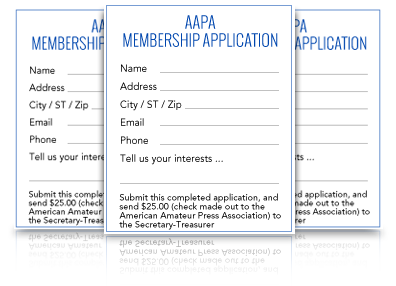

JOIN AAPA!

Become A Member!

Amateur journalism is a unique activity. Amateur journalists publish journals on paper & online & come from many perspectives: from deluxe letterpress printed journals, to Xeroxed newsletters, to artistically designed cards and ephemera. We embrace the spirit of being amateurs – loving what we do for pure joy and not financial gain – while creating top quality journals, zines, and homemade publications.

Amateur journalism is a unique activity. Amateur journalists publish journals on paper & online & come from many perspectives: from deluxe letterpress printed journals, to Xeroxed newsletters, to artistically designed cards and ephemera. We embrace the spirit of being amateurs – loving what we do for pure joy and not financial gain – while creating top quality journals, zines, and homemade publications.

Members receive ...

- The monthly bundle mailed via the postal service

- Access to the website and e-journals

- e-mailed updates

- Ability to publish your stories on AAPA

|

|